Industrial Biomimicry: Nature-Inspired Solutions for Advanced Manufacturing

Revolutionizing industrial processes through biological emulation, industrial biomimicry is reshaping manufacturing landscapes. This innovative approach draws inspiration from nature's time-tested strategies, offering sustainable and efficient solutions to complex industrial challenges. By mimicking natural structures and processes, companies are unlocking new potentials in product design, material development, and operational efficiency.

The concept of biomimicry in industry isn’t entirely new, with early examples dating back to the 1940s when Swiss engineer George de Mestral invented Velcro after observing how burdock burrs stuck to his dog’s fur. However, the systematic application of biomimicry principles in industrial settings has gained significant traction only in recent decades. This surge in interest is driven by the growing need for sustainable practices and the advancement of technologies that allow for more precise replication of natural structures and processes.

The Principles of Industrial Biomimicry

Industrial biomimicry operates on the premise that nature has already solved many of the problems we’re grappling with in manufacturing. By studying biological systems, engineers and designers can extract principles that can be applied to industrial processes. These principles often lead to solutions that are not only more efficient but also more environmentally friendly.

One key aspect of industrial biomimicry is the focus on circular systems. In nature, waste from one process becomes food for another, creating a closed-loop system. This principle is being applied in manufacturing to create more sustainable production cycles, reducing waste and improving resource efficiency.

Applications in Advanced Manufacturing

The applications of biomimicry in manufacturing are diverse and expanding rapidly. In material science, researchers are developing new materials inspired by natural structures. For example, the strong yet lightweight structure of honeycombs has inspired the design of aerospace materials, while the water-repellent properties of lotus leaves have led to the development of self-cleaning surfaces.

In process optimization, manufacturers are looking to nature for inspiration on how to improve efficiency. The swarm behavior of ants and bees has inspired new approaches to supply chain management and logistics, leading to more adaptive and resilient systems. Similarly, the energy-efficient movement of schools of fish has influenced the design of more aerodynamic vehicles and improved fluid dynamics in industrial processes.

Biomimetic Design in Product Development

Biomimetic design principles are increasingly being incorporated into product development processes. This approach not only leads to more sustainable products but often results in innovative solutions to long-standing problems. For instance, wind turbine blades inspired by the tubercles on humpback whale fins have shown increased efficiency and reduced noise pollution.

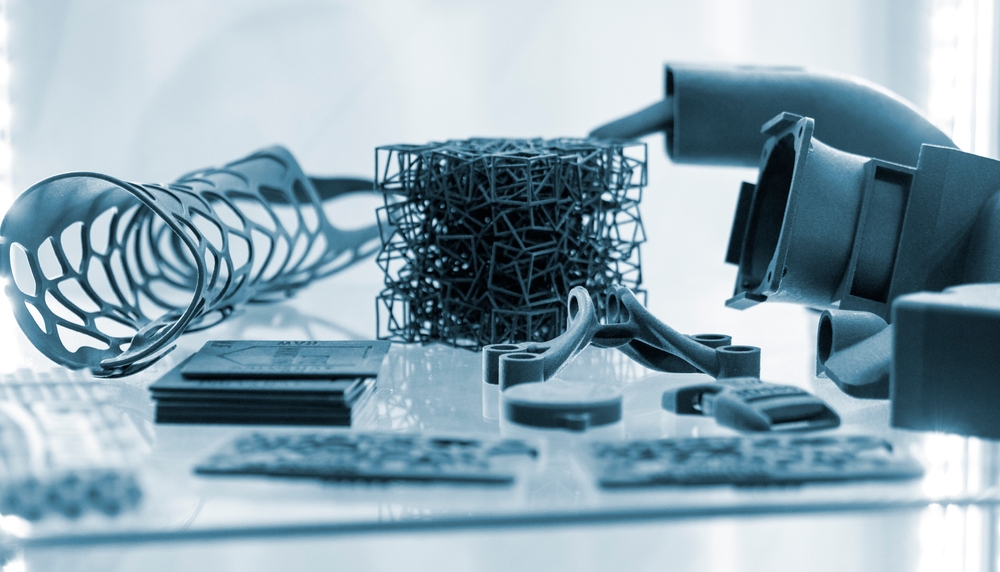

The use of generative design tools, which mimic evolutionary processes, allows engineers to create optimized structures that are often lighter, stronger, and use less material than traditional designs. This approach is particularly valuable in industries like automotive and aerospace, where weight reduction can lead to significant improvements in fuel efficiency.

Challenges and Future Prospects

While the potential of industrial biomimicry is vast, its implementation faces several challenges. Translating biological principles into industrial applications often requires significant research and development. There’s also the challenge of scaling biomimetic solutions from laboratory prototypes to industrial-scale production.

However, as technology advances and our understanding of biological systems deepens, the barriers to implementing biomimetic solutions are gradually being overcome. The future of industrial biomimicry looks promising, with potential applications ranging from self-healing materials to more energy-efficient manufacturing processes.

Key Insights for Implementing Biomimicry in Industry

• Start with function: Focus on the functional challenges in your processes and look for analogous solutions in nature.

• Collaborate across disciplines: Bring together biologists, engineers, and designers to foster innovative solutions.

• Invest in R&D: Allocate resources for long-term research into biomimetic solutions, as the payoff can be substantial.

• Think in systems: Consider how your biomimetic solution fits into the larger ecosystem of your industry.

• Embrace circular thinking: Look for ways to close loops in your manufacturing processes, mimicking natural cycles.

As industries continue to grapple with sustainability challenges and the need for innovation, industrial biomimicry offers a promising path forward. By looking to nature’s time-tested strategies, manufacturers can develop more efficient, sustainable, and resilient processes. The fusion of biological wisdom with industrial ingenuity is not just shaping the future of manufacturing; it’s creating a new paradigm for how we approach industrial challenges, promising a more harmonious relationship between industry and the natural world.